Juner Zhu, the battery ‘doctor,’ believes the electric vehicle revolution could be more sustainable.

Half of Americans would prefer to own a greener car — whether it’s a standard hybrid, a plug-in hybrid or a fully electric vehicle — says a recent Washington Post-University of Maryland Poll. This growing consumer interest has come none too early. According to a 2022 International Energy Agency report, gas-powered vehicle sales need to end by 2035 to stay in line with net zero CO2e emissions by 2050.

If these goals are met, battery production — the beating heart of the electric vehicle revolution — will go into overdrive. Annual lithium production, at more than triple the rate than it was a decade ago, is likely to increase exponentially. And the environmental and social ills associated with mining and battery disposal may further burden society.

Juner Zhu, Assistant Professor in the Mechanical and Industrial Engineering Department at Northeastern, has spent years with batteries on his mind, thinking through the dilemma of replacing one challenge — mitigating emissions — with another challenge — sustainable batteries. A critical factor, he says, is increasing the battery lifespan.

“There need to be people to understand if these batteries are holding up,” he argues, just as doctors assess the human body in an effort to ensure its longevity.

Zhu is that person. Throughout his postdoc and time as a professor, he has watched the industry retire more and more batteries, either repurposed for another use or ground up for parts. In an ideal world, he says, a Tesla battery could be fixed on the spot, not ditched. A big part of that is accurately diagnosing battery health and designing them to be refurbished, both of which are foci of Zhu and his research team.

“We spend so much energy and time, and design all the batteries, just to destroy [them]? That’s actually [losing] a lot of value. Why not just refurbish it?”

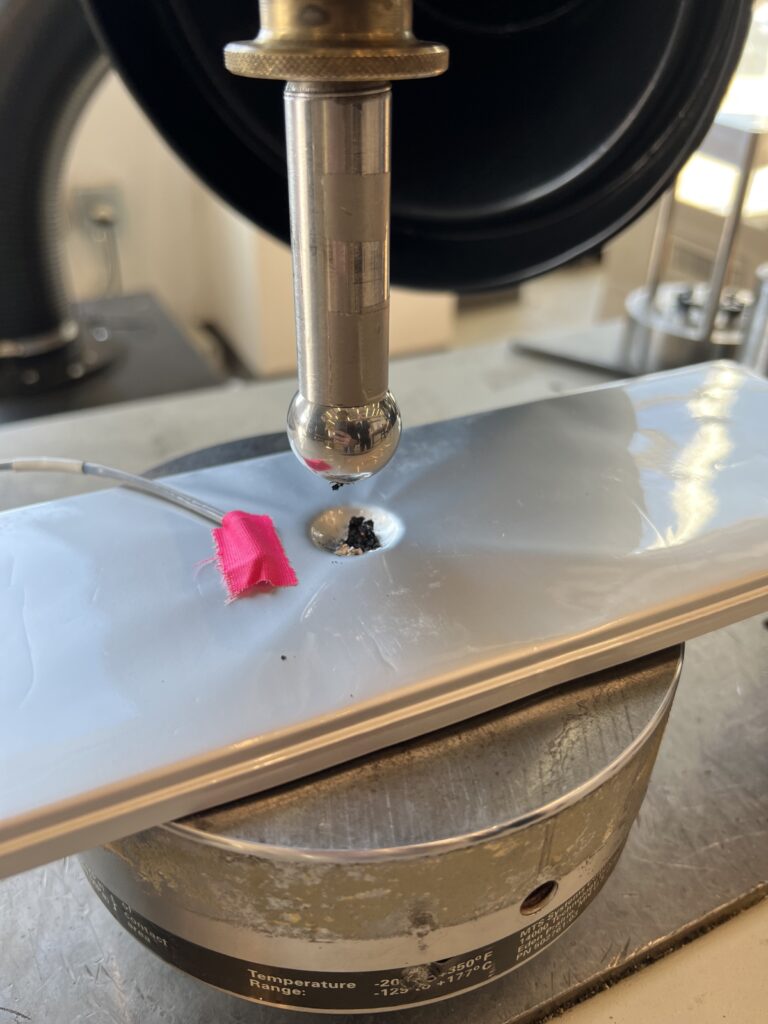

Most of Zhu’s work is developing diagnostic strategies for battery health. While battery health is often determined using electric signals or temperature monitoring, Zhu’s team is focusing on a unique approach involving mechanical measurements. A mechanical approach can provide more direct information on how batteries deform, fail and even explode. For example, it can detect if a battery is “swelling,” which means it’s in danger of leaking and catching fire. Additionally, mechanical assessments are usually faster.

Battery assessments are critical, because they help answer the question: When should a battery be recycled, given a new life or refurbished?

In a study published in EcoMat in 2022, Zhu’s team checked to see if the bending of the metal sheets within lithium batteries would cause the battery to ignite. While they did not find evidence of this, they found other indications that the batteries’ charging capacities and lifetimes were seriously impacted by this kind of wear and tear. They used a computer model of the bending to simulate the experiment, and the simulation agreed with their measurements.

In 2022, Zhu and his team, along with professors from MIT, established the Center for Battery Sustainability and proposed that the assessment of battery health be a bigger part of the conversation in the field. At the center, the researchers are combining data with machine learning and physics models to understand the stage of a battery within its lifecycle.

“I think that is actually a big opportunity for us. I feel it’s really interesting and exciting that we should provide some solutions for [making] batteries really sustainable,” says Zhu.

Recycle, repurpose or refurbish?

When a battery is no longer fit for use in an electric vehicle — due to its decreasing ability to hold a charge or increased risk of catching fire — there are a few options. One is to swap it out for a new battery and send the sick battery away.

“Typically, if an electric vehicle undergoes inspection, and the battery health is not sound, a dealer gives you a new battery pack,” says Zhu. The old battery pack gets sent to the dealer who then sends it out for recycling.

But recycling, by nature, is crude. It’s about melting down — not preserving — the elements of the object and refabricating them into something new.

Batteries are recycled through a “grinding process,” says Zhu, “mechanically destroying them into a very big mass. And then they will screen out, for example, the [battery] enclosure materials and keep only the … key components.” In the industry, it’s called a “black mass.” The process ultimately leaves you with raw materials and noticeably … no battery. In 2022, according to the United States Geological Survey, there were about 44 companies in Canada and the United States and 47 companies in Europe that recycled lithium batteries or planned to do so.

Another option is to give a battery a second life, the possibilities for which Zhu surveys in his team’s 2022 article in Cell Reports Physical Science. Common second-life applications include low-speed electric bicycles, energy storage for homes and street lighting, and backup for buildings and power grids. For these applications, the battery doesn’t have to operate at full efficiency.

Making refurbishing viable

Batteries consist of an enclosure structure, typically made out of steel or aluminum, and within that, minerals like lithium, cobalt and nickel. There are also electrolytes, in the form of liquid, which can be replaced to extend the life of the battery. But the trick with EV batteries is that they’re not designed for tune-ups. They’re bolted into the car and sealed shut like a vault. And if a single module is in need of repair, you can’t disconnect it from the larger pack.

Zhu wants to be able to look at any module in a battery pack, on the spot, and see exactly what it needs. “I want to pick them up. If I can do X-ray, or if I can do ultrasound on the battery [I can] just tell you ‘this battery is healthy’ or ‘this battery is safe.’” He hopes that the Center for Battery Sustainability will help promote this vision.

“Batteries should be redesigned so that we can easily open them, inspect and refurbish them.”

Story from the Science Media Lab.

Last Updated on April 12, 2024